Cooling Towers vs GeoExchange Method

When comparing and contrasting the traditional Cooling Tower method against the more environmentally-friendly GeoExchange method, it is important to understand how the former system contributes to energy loss while contributing to increases in pollution.

The Cooling Tower Method

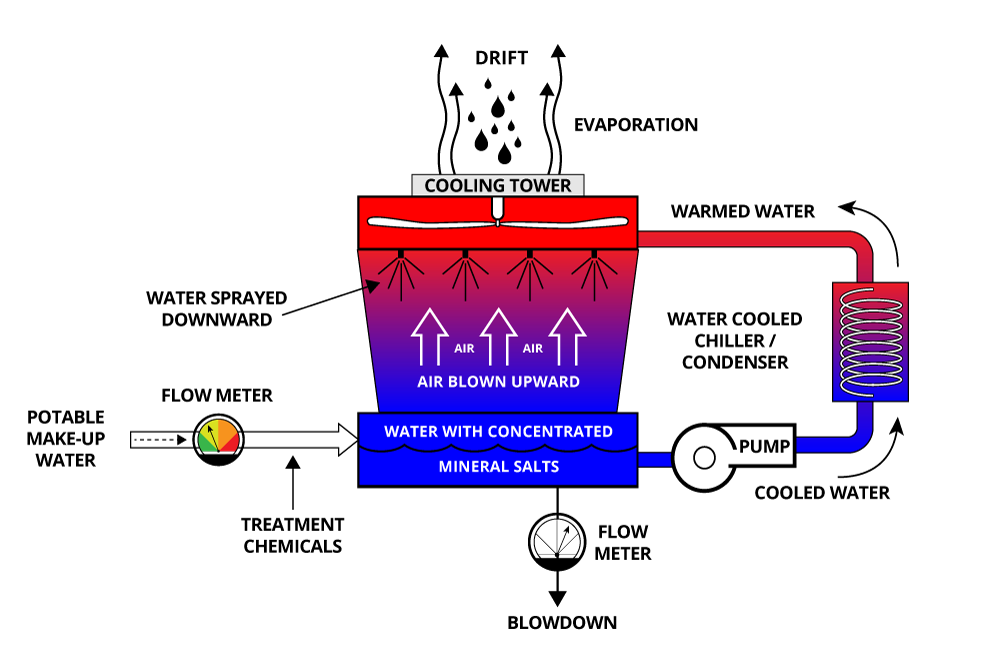

Within the cooling tower process, Potable water is used for makeup water and water treatment chemicals are added. Cooling towers are used to dissipate the temperature of warmed water by extracting energy from warmed water and emitting this energy to the atmosphere contributing to heat pollution.

The following figure illustrates how a cooling tower uses evaporation to dissipate the heat from the condenser water is evaporated into a moving air stream and subsequently discharged into the atmosphere. As a result, the remainder of the water is cooled down.

The image above shows a cooling tower use of evaporation, whereby some of the water is evaporated into a moving air stream. Drift (liquid water entrained in the air stream) is subsequently discharged into the atmosphere. Treatment chemicals and blowdown controls the concentration of dissolved solids. This is then discharged from the cooling tower, adding to water consumption.The GeoExchange Method

A Slim Jim® or Geo Lake Plate® assembly can be used to reduce the temperature of warmed condenser water by rejecting energy from the warmed water and dissipating it to the cooler Pond, Lake, River or Ocean.

The following figure illustrates a Slim Jim® assembly rejecting energy to the cooler Pond, Lake, River or Ocean whereby all of the warmed condenser water is cooled.

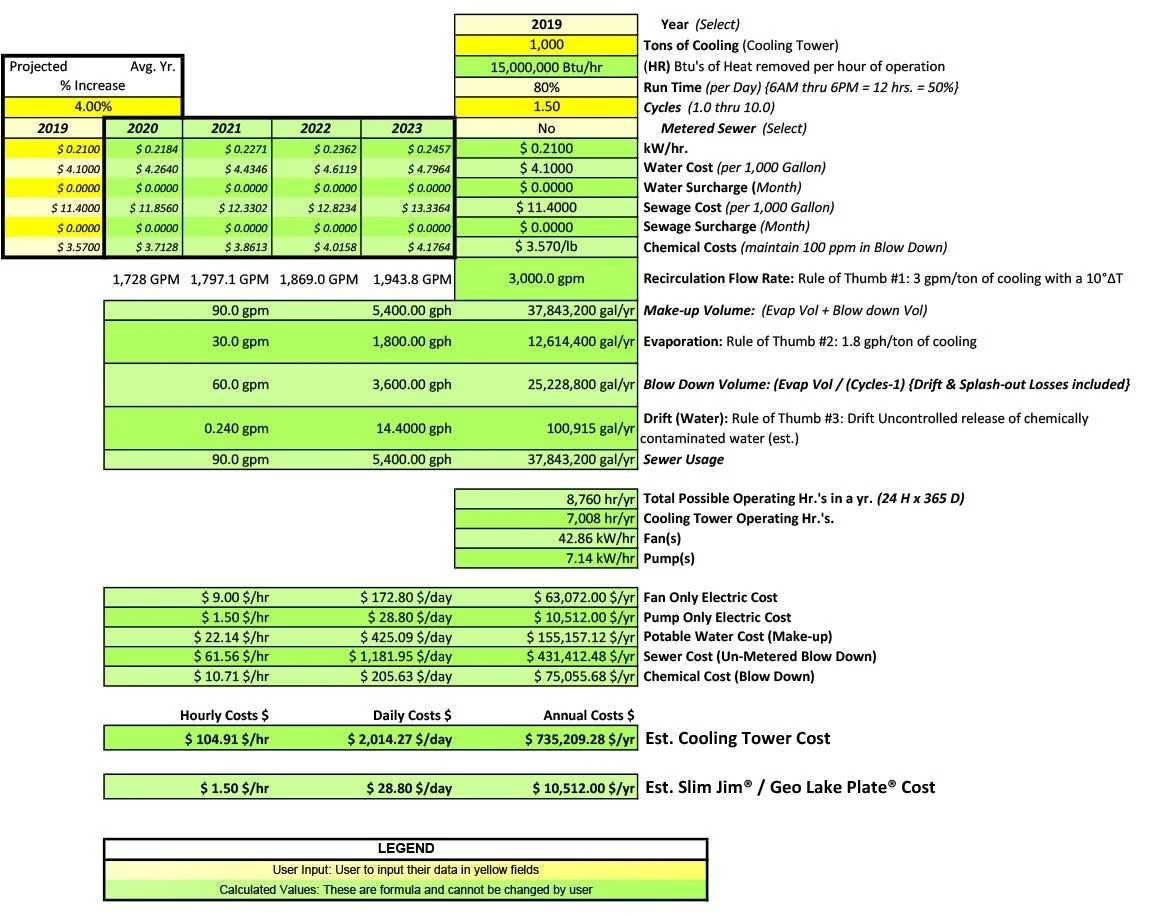

Subsequently during this process the use of clean potable make-up water, has been eliminated. Any make-up water for the body of water will be supplied by rain water or untreated ground water. Conserving the use of clean potable water.This Cooling Tower vs. Slim Jim® / Geo Lake Plate® operating cost comparison is provided as information only solely to exhibit the cost & water saving benefits when selecting the Slim Jim® / Geo Lake Plate®.

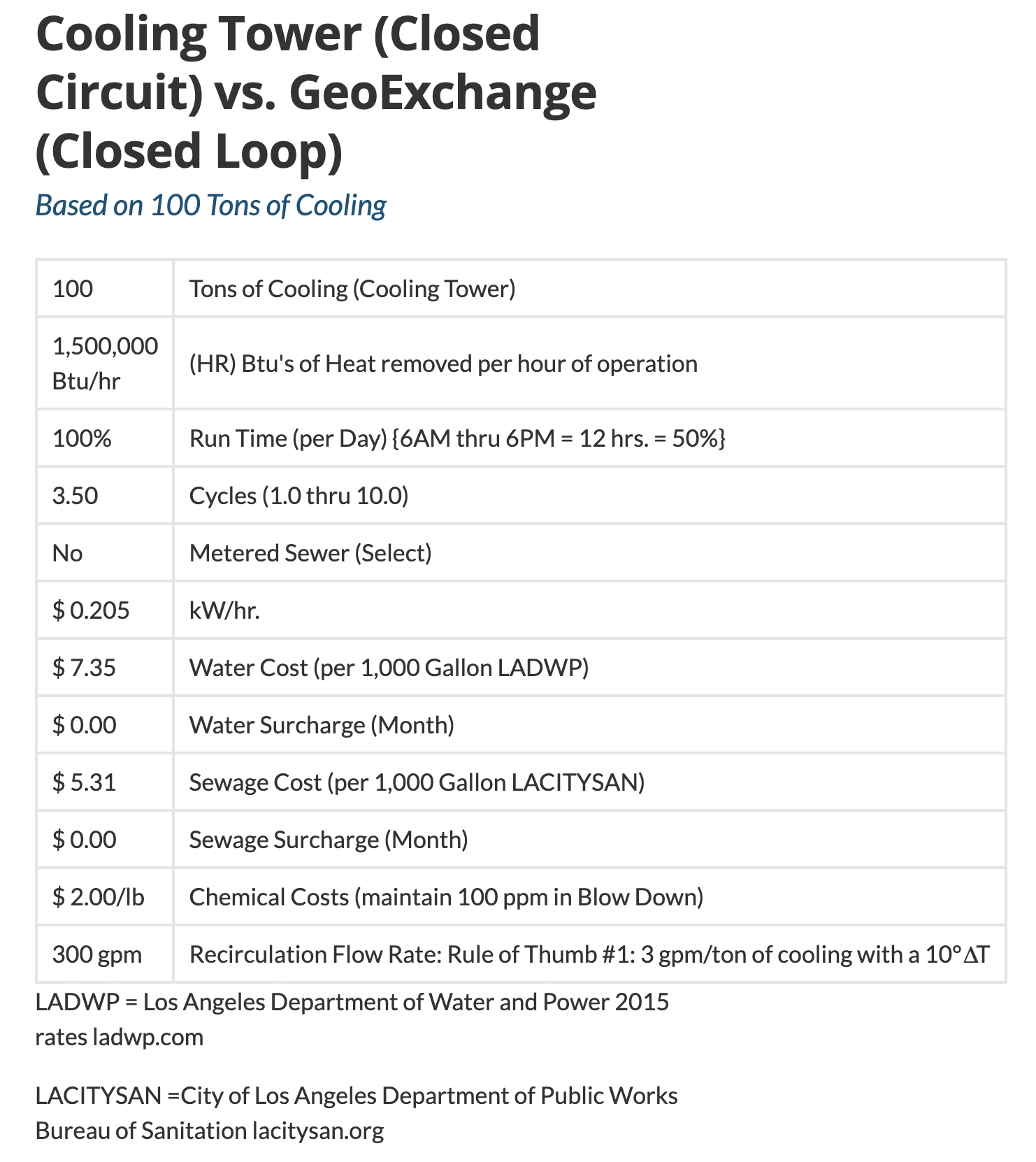

You may use this operating cost comparison for evaluating operational costs of a Cooling Tower vs. Slim Jim® / Geo Lake Plate® for your application. Your use of this information is subject to the limitations set forth below.This Cooling Tower vs. Slim Jim® / Geo Lake Plate® operating cost comparison is provided as information only to our customers solely to exhibit the cost & water saving benefits when selecting the Slim Jim® / Geo Lake Plate® for the their applications. We offer this analysis simply as information to be used for no other purpose. The validity and value of the results achieve depend critically upon the accuracy of the information provide. AWEB Supply disclaims any liability for the results obtain using this information, and SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. You are encouraged to contact AWEB Supply at 888.277.2932 to obtain more information or assistance on the Slim Jim® / Geo Lake Plate® product.Additional Water Savings through Energy Reduction with GeoExchange 100 Tons of Cooling

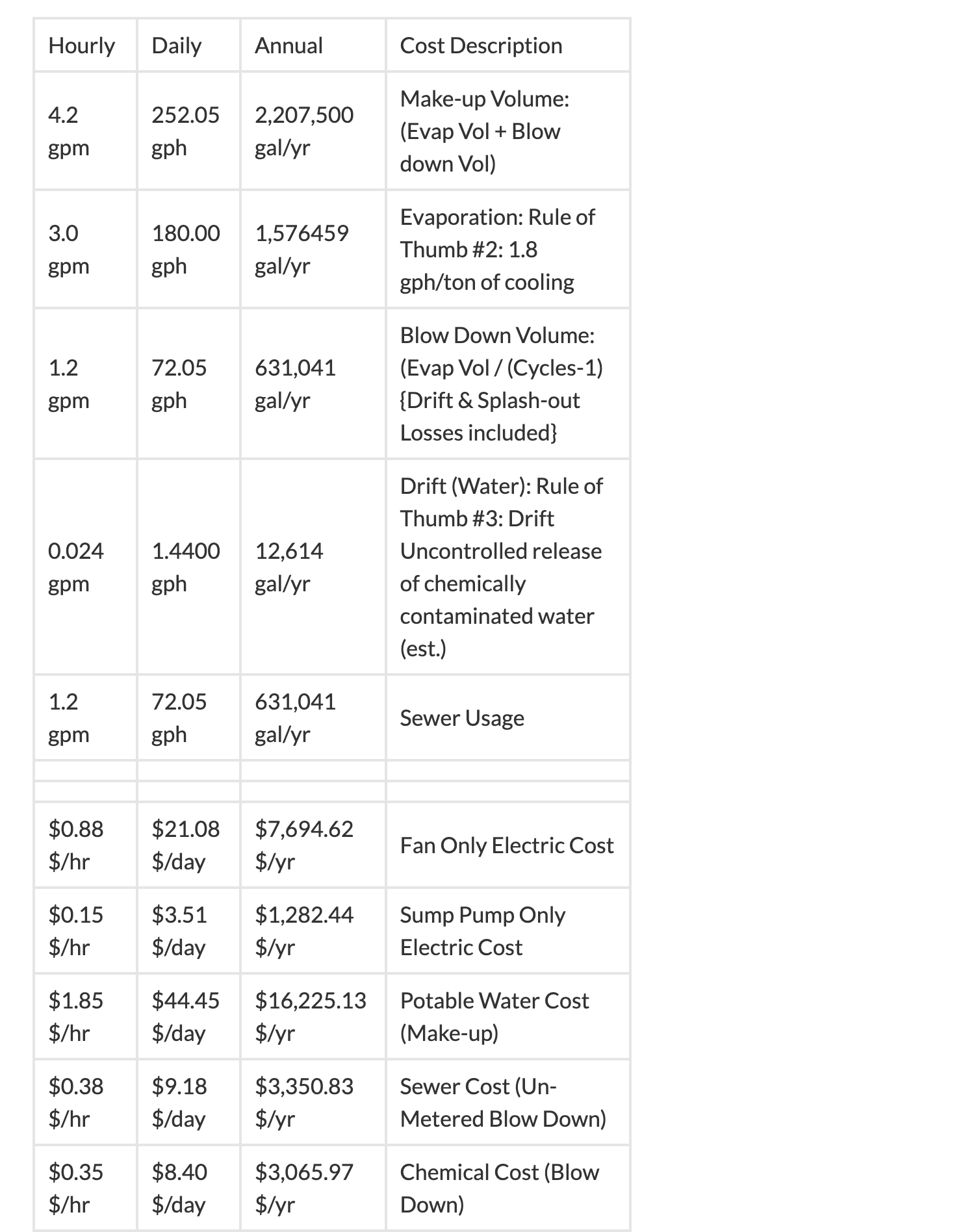

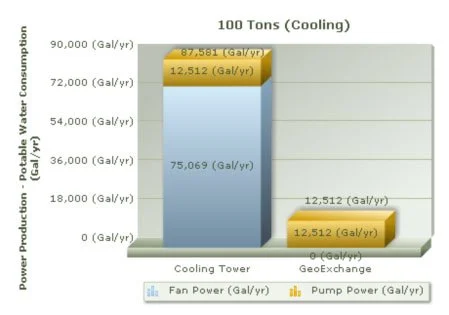

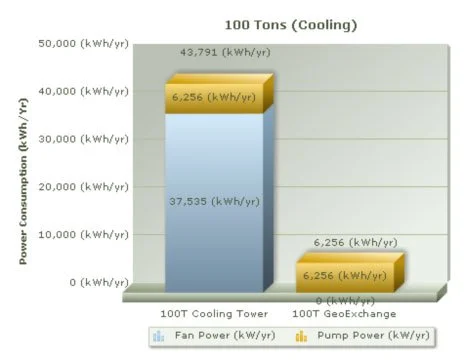

It takes an average of 2 gallons of water to produce 1 kilowatt-hour of electricity

In this slide, the graph on the left shows the energy consumption for the cooling tower to be 43,800 kilowatt hours per year. This breaks down to 37,500 kilowatt hours per year to run the fans and 6,300 kilowatt hours per year to run the pump. The energy consumption for our GeoExchange system is only 6,300 kilowatt hours per year to run the pump. This reduces energy consumption by 37,500 kilowatt hours per year.

Additional Potable Water Savings of 75,069 Gal/yr with GeoExchange through Energy Reduction

Important Facts and Calculations

100 tons of cooling tower capacity uses/evaporates 252 gallons of potable water per/hr. This calculates out at:

6,000 gallons of potable water usage per day*

184,000 gallons of potable water usage per month

~2.2 million gallons of potable water usage per year

Replacing this type of cooling tower with a closed loop GeoExchange system could conserve ~2.2 million gallons of potable water on an annual basis.

For every 1,000 tons of cooling capacity conserved, consumption of potable water could be reduced by ~22.1 million gallons annually.

*Running 24 hrs a day / 3.5 cycles