Slim Jim® - Geo Lake Plate®

Installation Requirements and Criteria

Slim Jim® - Geo Lake Plate® Installation Requirements / Criteria

Water Applications:

Slim Jim® 304 Stainless Steel is recommended for “Fresh Water Applications Only”

Geo Lake Plate® 316L Stainless Steel is recommended for “Fresh Water Applications Only”

Geo Lake Plate® Titanium is recommended for “Brackish and Seawater Applications”

The following applies to all Slim Jim® (304 Stainless Steel) Geo Lake Plate® (316L Stainless Steel & Titanium) single plate or assembly(s) for proper operation and maximum performance:

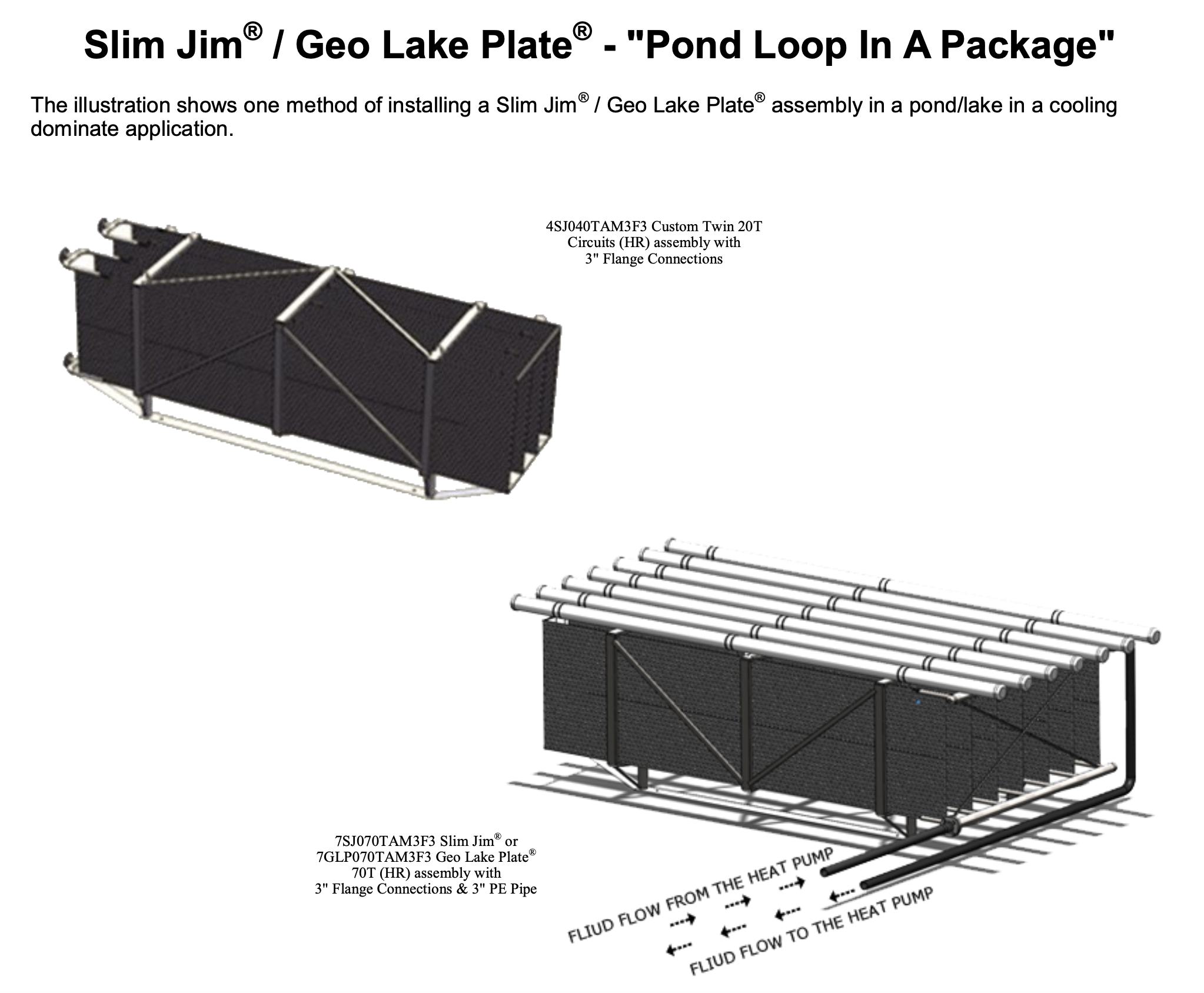

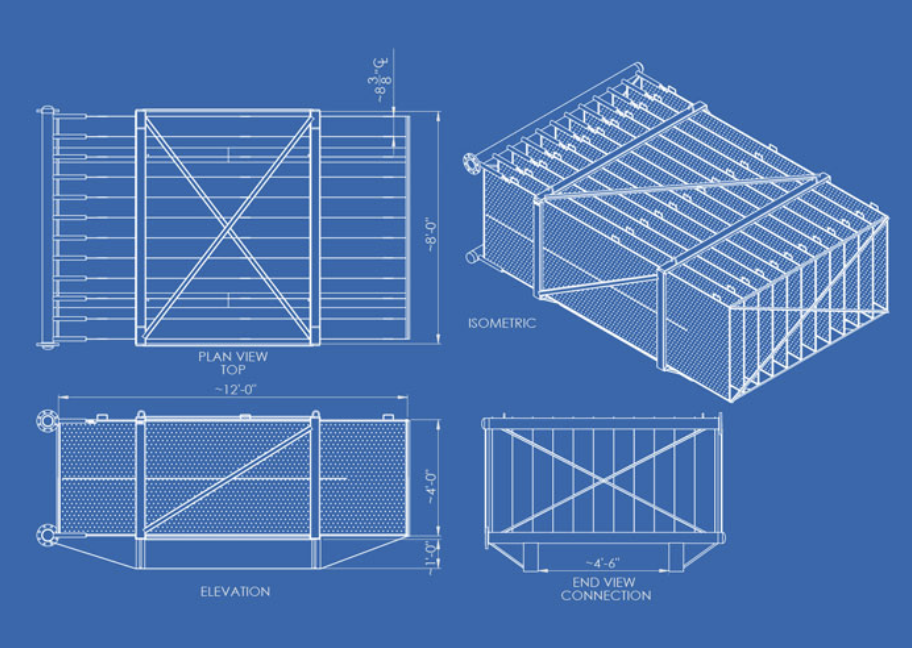

Plate/Assembly(s) must be installed to stand or suspend/hang vertical completely submerged in a body of water.

The fluid flow from the Heat Pump(s) or Chiller(s) equipment must enter the lowest connection on the plate/assembly(s).

The fluid flow returning to the Heat Pump(s) or Chiller(s) equipment must exit the highest connection on the plate/assembly(s). This will ensure any air remaining air the system will not be trapped in the plate/assembly(s).

The body of water must be adequate to accommodate the load requirements.

The plate/assembly(s) must be supported off the bottom above silt or mud. This can be accomplished with legs or other means (see examples).

The plate/assembly(s) can be suspended from piers or docks, but must be secured and protected for the conditions in which they are installed.

The recommended minimum installation depth should be 3' to 4’ of water from the top of plates. In northern climates we recommend a minimum of two (2) foot clearance beneath freeze line and top of plate/assembly(s).

DO NOT TIGHTEN/TORQUE ANY INLET/OUTLET CONNECTION WITHOUT USING A BACK UP WRENCH TO COUNTERACT TORQUE

This is necessary for proper operation and maximum performance follow the single Slim Jim® / Geo Lake Plate® or assembly.

Stabilizers can be added to allow the single Slim Jim® / Geo Lake Plate® or assembly to float just beneath the surface of the water until placed into position for submerging. Once positioned and flushing of the loop system has started, the stabilizer allows the plate/assembly(s) to slowly sink staying vertical until resting on the floor of the body of water. The stabilizer(s) are not removed after the installation is completed.

Systems on any earth/lake loop in extreme conditions may call for auxiliary heat. When the return water to the unit is ≤32°F and the unit calls for auxiliary heat, the auxiliary heat should be designed to stay engaged until the thermostat(s) is fully satisfied regardless of loop type. In most applications a relay (Fig 1) will need to be added to keep the supplemental heat engaged until the thermostat(s) are fully satisfied. This will allow for down time and loop regeneration. Additional information may be obtained on this subject by contacting AWEB Supply.

Note: Multiple handles are standard on the single Slim Jim® / Geo Lake Plate® or assembly(s). The handles are designed to support the empty weight of the plate only during handling and assembly. The handles are not designed for permanent suspension/hanging of the single plate or assembly(s) and may result in damage to the plate. Stainless Steel Hose Clamps or Stainless Steel Screw Bands can be used to attach the Stabilizer to the handles. Connecting the Stabilizers to the handles or support frame will keep it vertical during its decent as the plates are flushed until the assembly is resting on the floor of the body of water.